Durable anti-icing materials

Ice accretion has a negative impact on critical infrastructure, as well as a range of commercial and residential activities. The OPERA Lab investigates new ways of understanding, controlling, and reducing ice accumulation. Back in 2016 we explained how interfacial cavitation, a surface instability, can be exploited to fabricate coatings with remarkably low ice adhesion. This also led to the development of ultra-durable icephobic materials. A year later we formulated a theoretical model to help explain another phenomenon that can reduce ice adhesion: interfacial slippage.

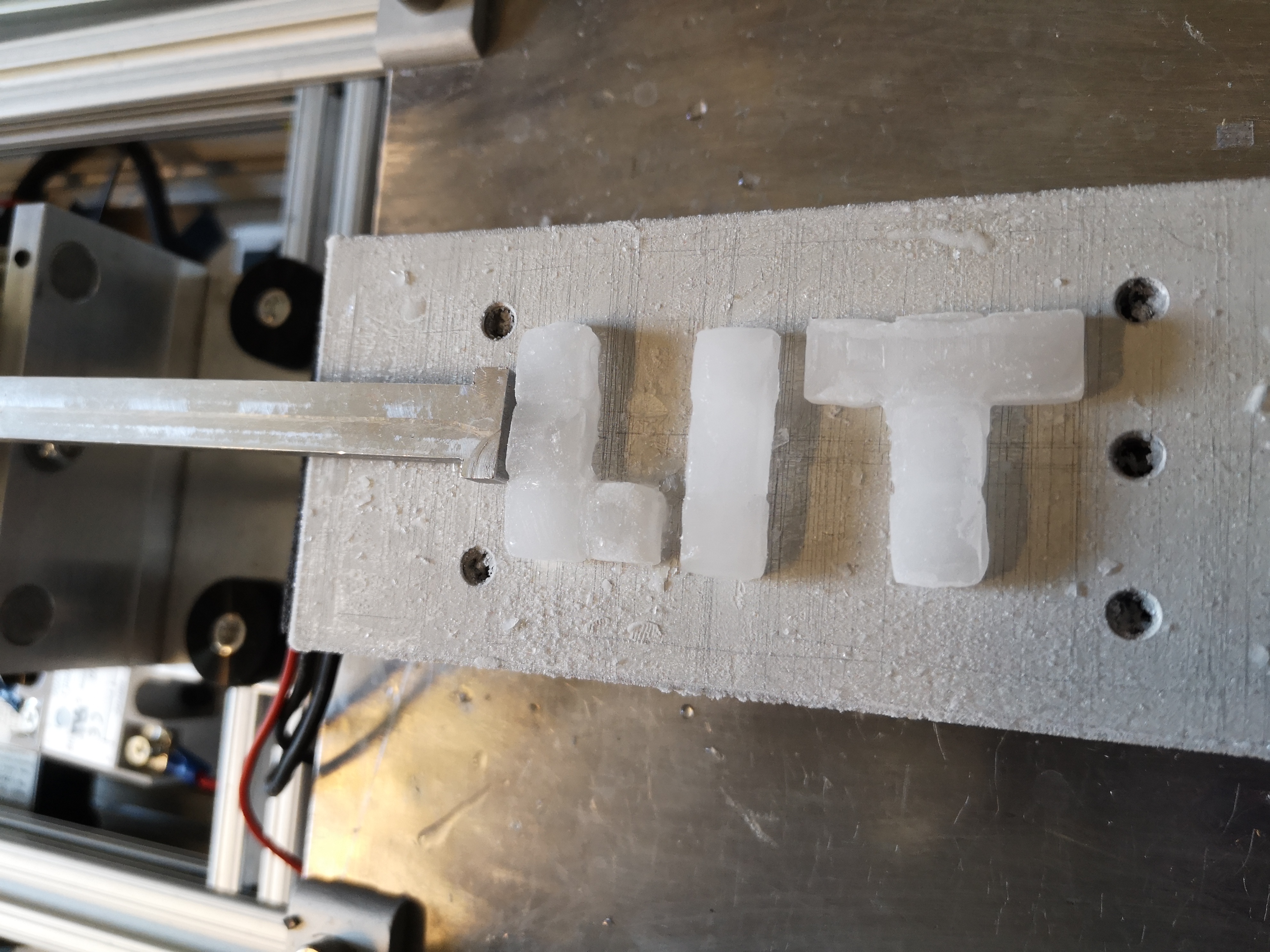

In 2019 we had a scientific breakthrough in terms of ice adhesion: the common metric everyone had previously used to characterize the bonding between a surface and ice, it’s ice adhesion strength, was an incorrect, or at least incomplete, characterization tool. For interfaces larger than a few cm, ice fractures through crack propagation which does not depend on the ice adhesion strength, but rather the interfacial toughness. Our study explaining the mechanics behind this, as well as how to generate Low Interfacial Toughness (LIT) materials, was published in Science.

Fluorine-free omniphobicity

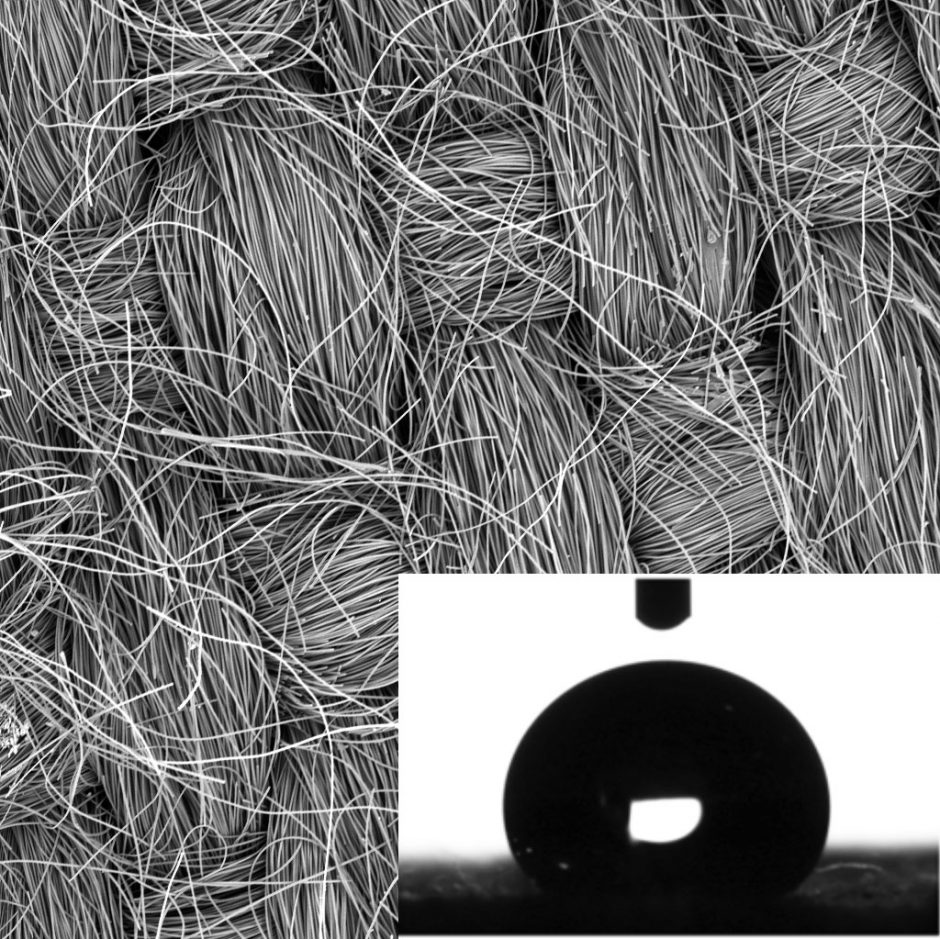

Coatings repellent to many different liquids, including hazardous and low-surface-tension liquids like oils and alcohols, are termed omniphobic. Traditionally all omniphobic surfaces required PerFluoro-Compounds (PFCs), but these have been shown to be toxic and were banned in 2015 by the EPA. At UBCO we are pioneering a new generation of PFC-free omniphobic surfaces that can be applied to any substrate.

Sustainable textile modification

Waterproof jackets around the world fall into two categories: those that repel oils, and those that are PFC-free. We’re fighting that limitation by developing the first PFC-free, oil-repellent textile finishes. And we’re not alone. With help from Arc’teryx, lululemon, and the DND, hopefully together we can crack with worldwide issue!

Fighting malaria with natural oils

Malaria ranks as one of the deadliest diseases worldwide. One promising method for combating malaria is the development of chemical additives that kill or deter the mosquitos that transmit the disease. However, many impoverished nations facing a malaria epidemic cannot afford the carriers of these additives. The most striking example is paint. We are developing an anti-mosquito technology fabricated from inexpensive, recycled paint. We’ve teamed up with Loop Recycled Products, an Ontario-based paint company that recycles unused, stagnant paint, and re-sells it worldwide. Loop recently secured exclusive rights to use Kyzox, an anti-mosquito additive, in North America. Our team is optimizing the repellency of the anti-mosquito recycled paint, distributing the paint to community partners in Ghana, Nigeria, and the Dominican Republic, and assessing its efficacy at curtailing malaria in real-world conditions.

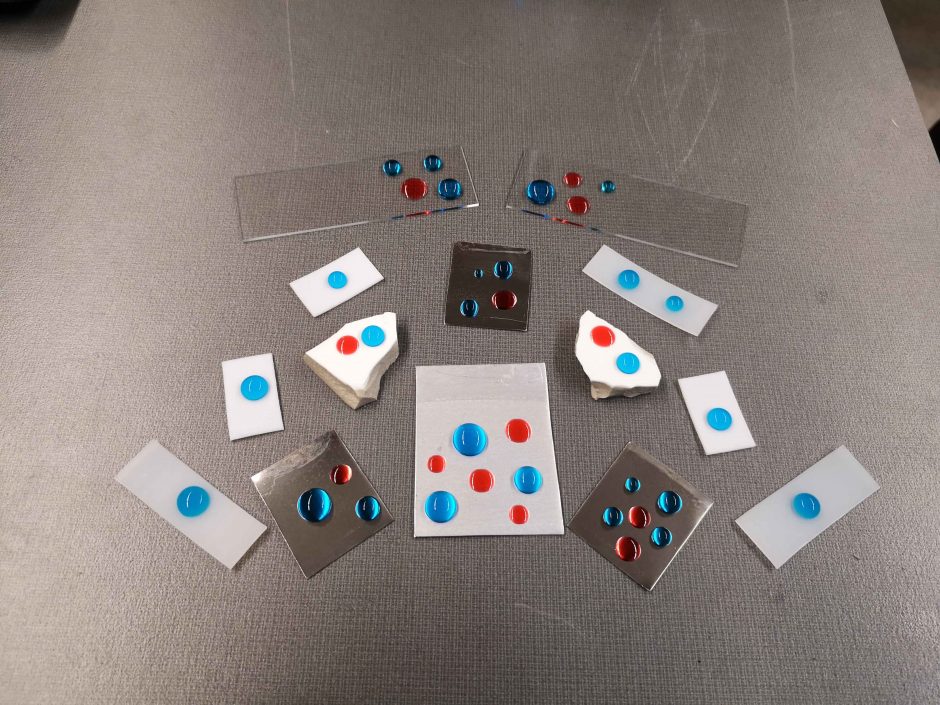

Sensor-embedded coatings: Protection + Detection

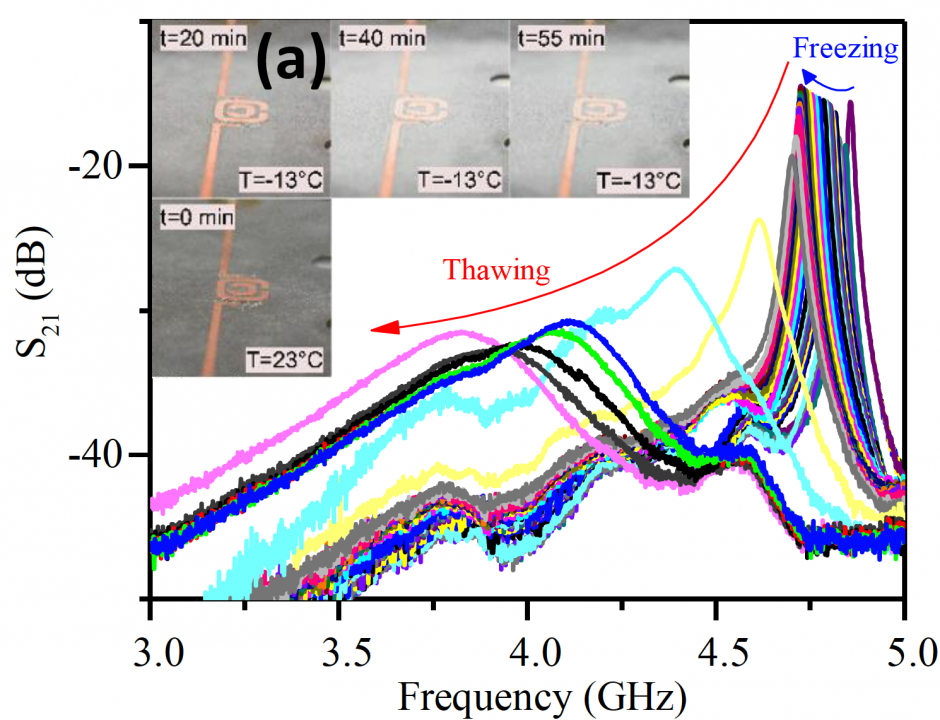

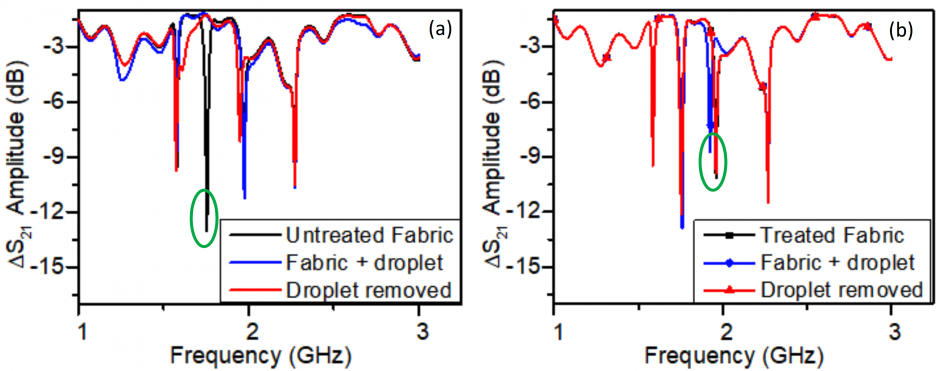

Repellent coatings offer protection from potential liquid, solid, and gaseous foulants. But why stop there? If your coating is protecting your surface from a dangerous foulant, wouldn’t you also like to know it’s there? In collaboration with Dr. Zarifi we’ve pioneered a protect + detect strategy by embedding sensors within repellent coatings. This allows us to monitor, for example, when a hazardous liquid is atop a coated textile (so you can shake it off) or the growth of ice on an aircraft (so you can de-ice).

High strength, omniphobic paper

Plastic sheets are used across many industries worldwide. Their good mechanical properties combined with their hydrophobicity make for ideal, waterproof barriers. But what if sustainable, recyclable paper could be engineered to offer the same performance? What if you grocer didn’t need to ask “paper or plastic?” because the paper outperformed the plastic?

Drag reduction in turbulent flow

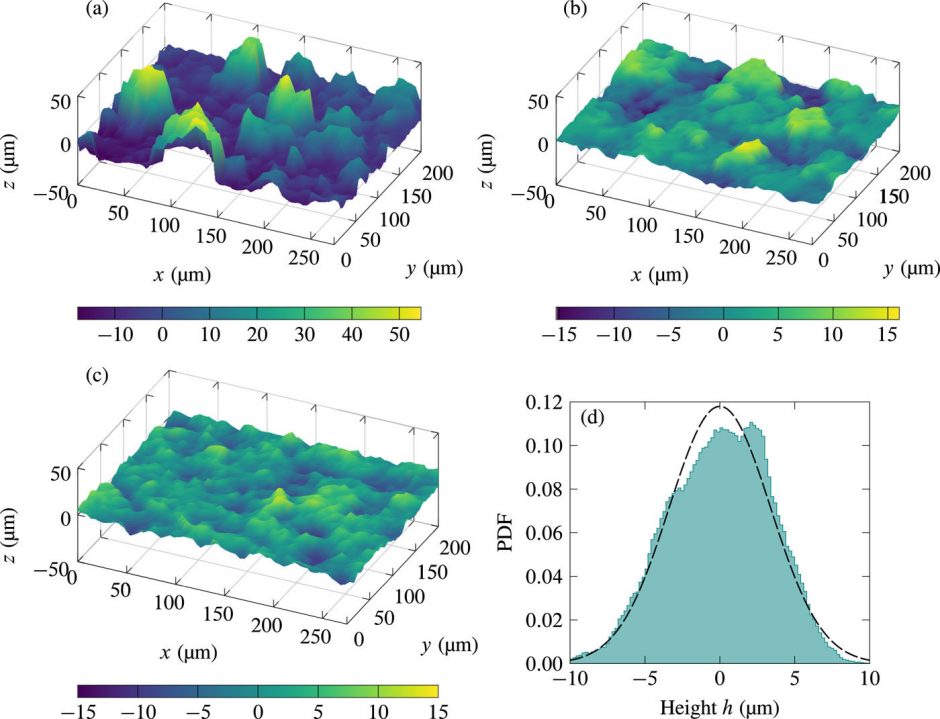

One of the exciting applications of water repellent surfaces is their use for friction drag reduction. About 60% of the fuel consumed by large ships goes directly to overcoming the frictional drag of the water. By coating the side of a ship with a superhydrophobic surface, much of this friction can be avoided. Or, at least, this is the case for laminar flow. Recently, we began understanding if and how superhydrophobic surfaces can reduce friction drag in turbulent flow.

When a superhydrophobic surface enters a liquid, it takes with it a large volume of entrained air!